An autonomous mobile robot (or AMR) is an intelligent machine that can understand, navigate, and react to its environment while performing certain tasks — all without human control or supervision.Autonomous mobile robots in warehouse settings, as an example, may be used for anything from sorting, picking, and packing, to batching, transportation, and fulfillment. Doing so addresses one of the biggest challenges in all industries — the labor crisis — and also provides specific operational benefits: AMRs save time, enhance productivity, and can ultimately increase profitability.

Their wide-ranging capabilities make autonomous mobile robots attractive to industrial decision makers. However, there are also several potential detractors:

All things considered, autonomous mobile robots are the long sought-after solution for many companies. Equally as important is acknowledging what AMRs are not:

In the age of Industry 4.0 and the rapidly expanding Industrial Internet of Things (IIoT), it’s easy to lump technologies together, but that could lead to missing out on the dynamic aid of fully autonomous technology.

Autonomous mobile robot applications range in complexity and function. The versatility, adaptability, and ease of use of the technology makes it easy for AMRs to do mundane non- value-add tasks such as carrying components or other items between unique locations.

Warehousing and distribution centers commonly use AMRs to load, unload, stack, and retrieve pallets of products. But managing large volumes of goods is just one benefit. Likewise, picking “eaches” — a task growing in concert with the e-commerce industry — is an ideal application. Bringing goods to people, as is the case of shuttling merchandise between operators or departments, is also a time-saving benefit of AMR deployment.

In 2022 and beyond, logistics operations are poised to use more AMRs in manufacturing environments, but that doesn’t preclude growth in industrial sectors. Factories are increasingly integrating autonomous mobile robots for limited manufacturing-related tasks, and an estimated 53,000 facilities will deploy mobile robots within the next three years.1

As in warehouses, manufacturing facilities are finding AMRs perfect solutions for truck/dock unloading, movement of products with production facilities, and end-stage processes like pallet-wrapping for outbound shipments. There is a significant push to reduce the time that scarce and fully trained employees spend on non-value-add activities in all areas.

Like any investment, there are hard and soft costs to consider with AMRs. Machine prices can vary dramatically based upon the included features, and soft costs encompass impact on capacity, productivity, labor, and other facility benchmarks as determined by the user.

Given the variables, putting a strict time frame on achieving full return on investment (ROI) is difficult. Popular yet inexact estimates range anywhere from 12 to 18 months2, and sometimes much longer.

Automation is usually implemented to realize positive cash flow in the long-term, so if a short-term ROI is possible it is wise to consider the option. AMRs that are completely independent also reduce the implementation time, which can often delay the start of the financial benefit that leads to the ROI.

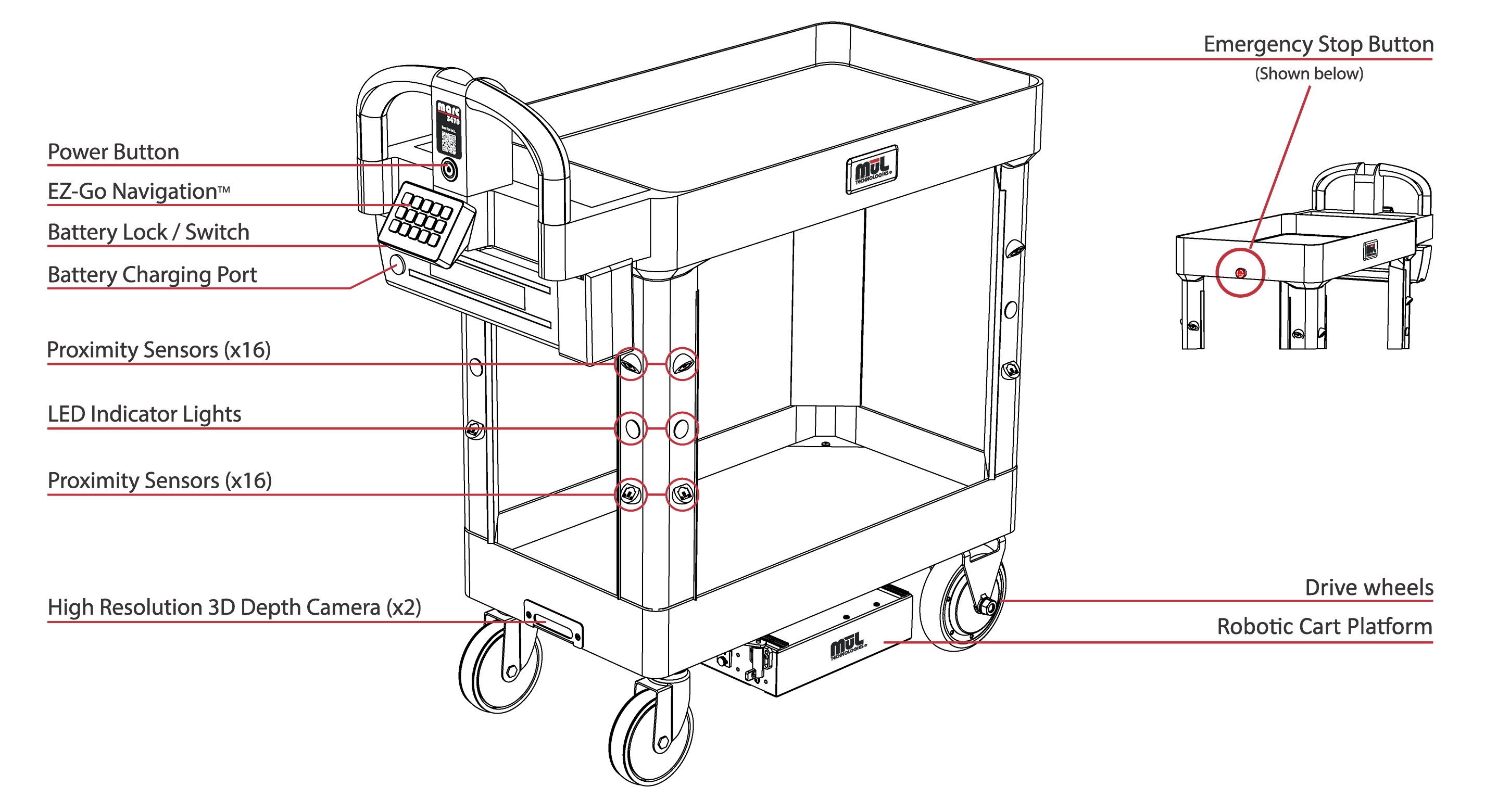

Autonomous mobile robots are highly attuned to their environments. Advanced systems of cameras and sensors guide them on paths and are designed to avoid potential collisions. Facility structures, products, and people are in no danger around AMRs — a direct contrast to human-operated warehouse equipment (e.g., forklifts, pallet jacks, etc.), which lack a comparable number of built-in safety features compared to AMRs, and are also subject to operator error.

Deciding to use autonomous mobile robots and actually deploying them are two very different things. Careful consideration must be given to how implementation will impact your processes, operational systems such as ERPs, and your personnel.

Establishing an internal Robotics Committee to gain perspectives from throughout your organization and to manage the budget is a necessary first step. This committee also serves to identify and vet potential AMR suppliers and platforms that align with your business model.

Traditionally, once the committee selects an autonomous mobile robot there is a second phase of activities required to prepare your facility for using the AMR:

With MūL Technologies Mobile Autonomous Robotic Cart (MARC®) few — if any — of these time-consuming and sometimes costly second phase steps are necessary.

MARC® has the brains to map your facility, avoid obstacles, and get things where they need to go on time. MARC® is a powerful performer, but the technology is easy to operate right out of the box! No need for WiFi, complicated facility infrastructures, or steep learning curves — that’s a win-win for your business and your workers!

The autonomous mobile robot market is projected to hit $22.15 billion by 2030 — a whopping 34.3% CAGR over the next 8 years.3 E-commerce, warehouse automation advances, and a steady increase in adopting AMR technology is further fueling the rapid growth.

Opportunities are growing in areas outside of warehousing, manufacturing, and distribution, too. Cleaning services, hospital and healthcare settings, the hospitality industry, grocery stores, and security patrols are also beginning to leverage the advantages of AMRs.

Autonomous mobile robots are on-trend to become the rule rather than the exception in many industries, and with good reason: There is clear opportunity, growing need, and exceptional solutions like the MūL Technologies Mobile Autonomous Robotic Cart (MARC®).

Practical, affordable, and dynamic, MARC is everything you want in an autonomous mobile robot (except the pricey, over-designed “bells and whistles”):

SOURCES

1Robotics Business Review, Mobile Robots Rapidly Mainstreaming - By 2025, AGVs and AMRs Deployed in 53K Facilities, Undated

2Robotics 247, How to Manage Your Autonomous Mobile Robot Return on Investment, April 24, 2022

3Globe Newswire, Global Autonomous Mobile Robot Market (2022 to 2030) - Opportunity Analysis and Industry Forecasts, February 2, 2022